Stamping process

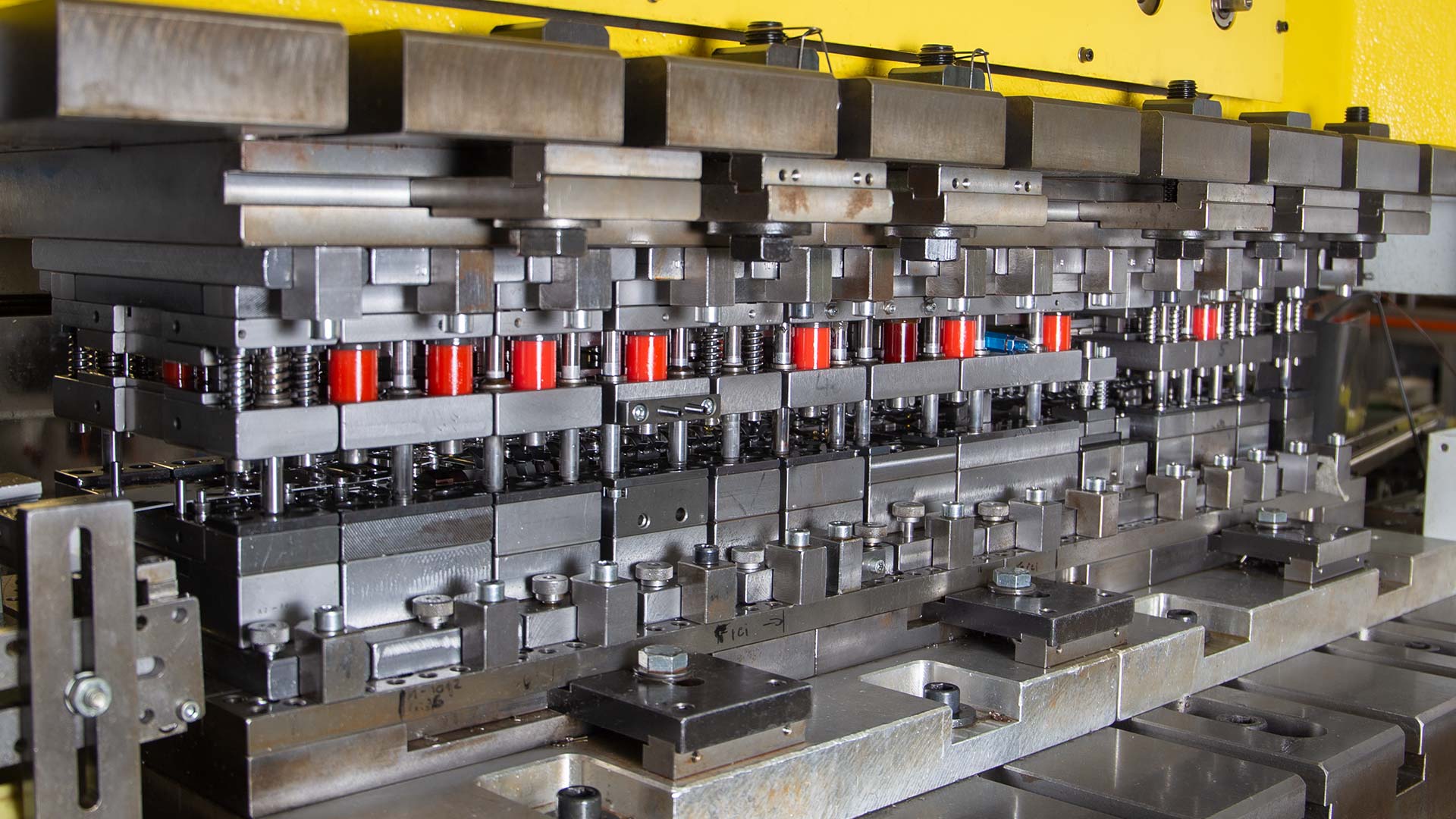

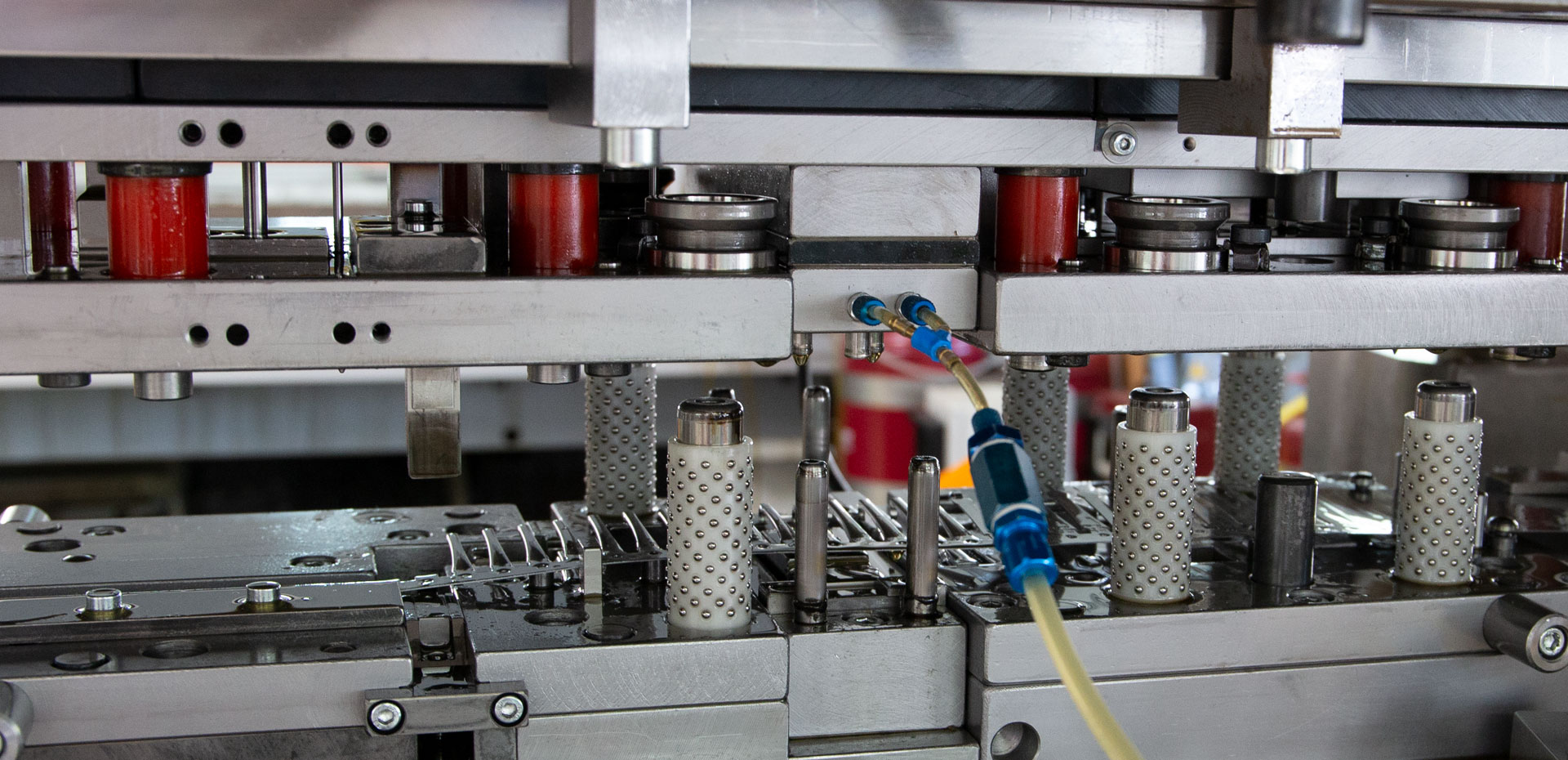

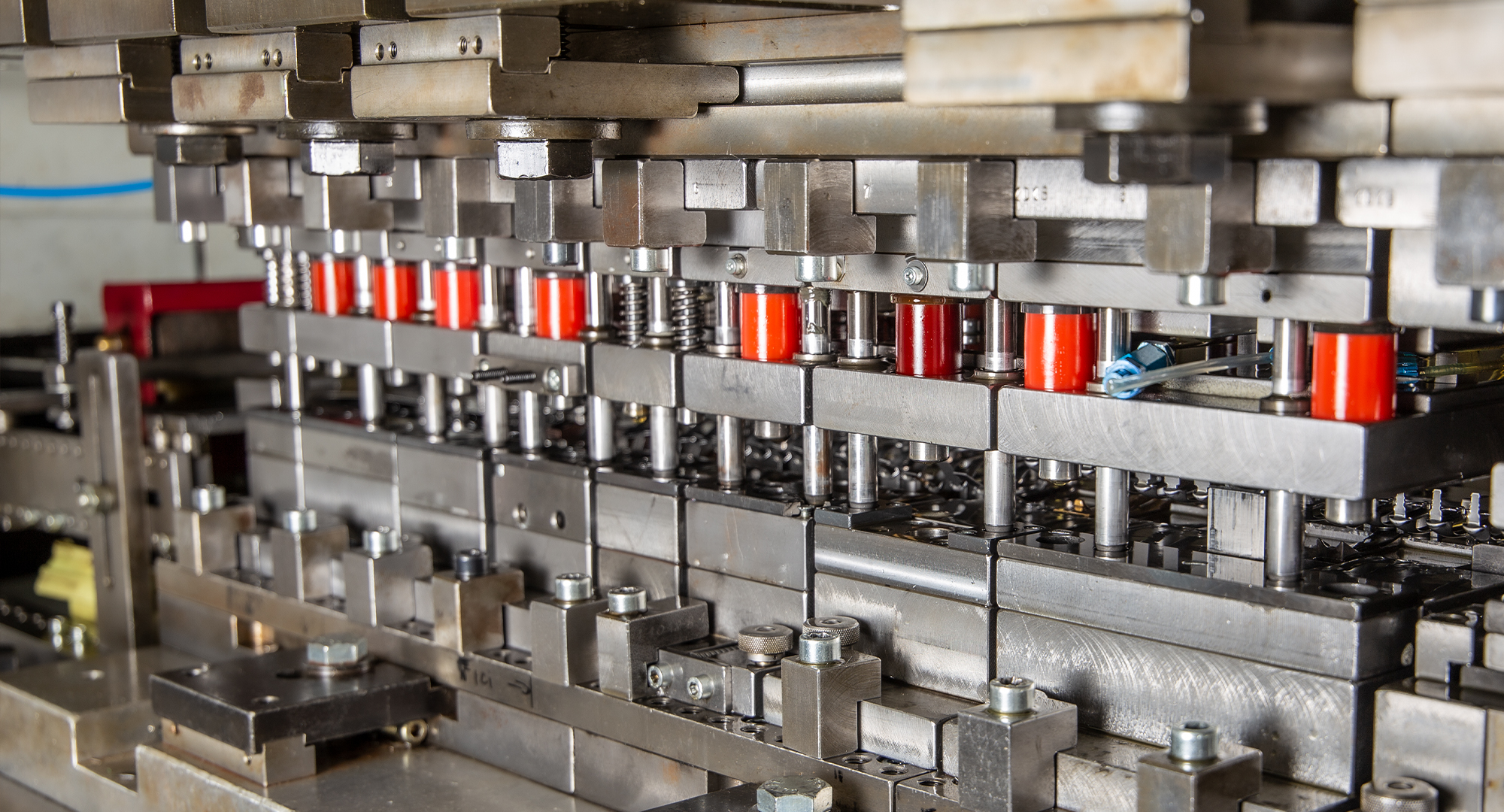

We cut, stamp and form metal components on state-of-the-art follow-on composite tools.

Our automatic stamping machines are capable of a pressing force of up to 100 tons and a lifting frequency of up to 1200 strokes per minute. The strip material used is up to 320 mm wide and between 0.1 mm and 2.0 mm thick. It can be processed in tools of a length of up to 2 metres.

We work with steel, stainless steel and also nonferrous metal strips.

The company’s construction and own toolmaking shop develops single or follow-on composite tools according to the required quantities. Each year several hundred million stampings are thus produced both economically and with high precision for our customers worldwide.